Raise Results with Our Materials Test Lab Experience

Wiki Article

Putting Materials to the Examination: Exploring the Function of Materials Test Labs

Materials examination labs play a vital role in making certain the top quality and dependability of numerous materials made use of in industries such as aerospace, manufacturing, and building. With a mix of advanced methods and customized devices, materials examination laboratories are able to assess the properties of steels, polymers, composites, and various other products under various problems and stress factors. This article will check out the relevance of products screening, the kinds of products tested, testing methods and tools utilized, as well as the applications of products examination results.Importance of Products Testing

On a regular basis examining the high quality of materials is essential in ensuring the honesty and security of products in numerous markets. Materials testing involves subjecting products to different examinations and experiments to examine their mechanical, physical, and chemical residential properties.One of the vital reasons materials screening is essential is the guarantee of product top quality. With rigorous screening, suppliers can determine any flaws or weaknesses in the products used for their items. This enables them to make necessary renovations to enhance the total quality and efficiency of their products. Materials testing aids in identifying prospective concerns that may occur throughout the item's lifecycle, such as wear and tear, rust, or architectural failings. By dealing with these problems early on, producers can avoid pricey recalls, lawsuits, and reputational damage.

By subjecting materials to numerous examinations, producers can identify their resilience, resistance, and strength to exterior elements such as heat, stress, or chemicals. Whether it is automobile parts, medical devices, or building and construction products, materials screening assists in recognizing any type of potential security dangers and establishing ideal procedures to mitigate them.

Sorts Of Materials Checked

Numerous types of products are evaluated in products test labs to review their mechanical, physical, and chemical buildings. These materials can include a large range important, consisting of metals, polymers, ceramics, compounds, and even natural products such as timber and concrete.Metals are generally evaluated because of their widespread use in different sectors. These tests evaluate properties such as tensile stamina, firmness, and ductility. Polymers, on the various other hand, are tested to identify their flexibility, thermal security, and resistance to chemicals. Ceramics are examined for their resistance, brittleness, and toughness to heats. Composites, which contain two or more various products, are reviewed to understand their overall performance, including elements like longevity, adaptability, and strength.

All-natural materials like timber are checked to evaluate their strength, dampness content, and resistance to degeneration (materials test lab). Concrete is one more commonly checked material, with examinations focusing on its compressive toughness, toughness, and resistance to environmental variables

Along with these products, products examination labs likewise evaluate layers, paints, adhesives, and different other products utilized in building and construction, manufacturing, and various other industries. By subjecting these materials to strenuous testing, designers and researchers can collect important information to inform product option, style optimization, and top quality control processes.

Checking Techniques and Tools

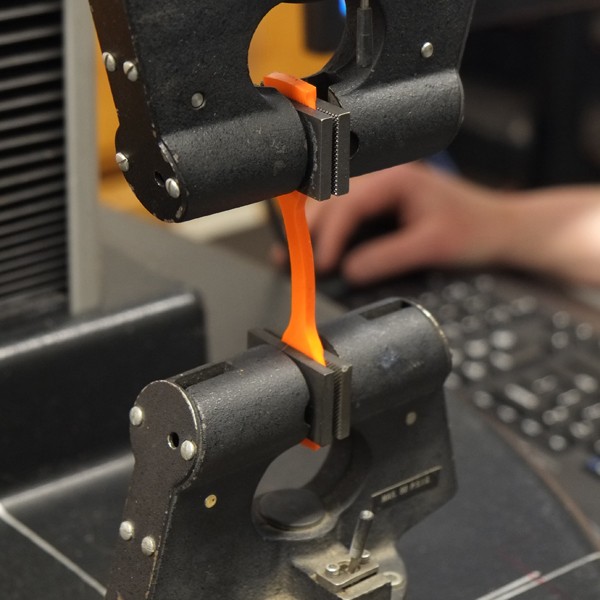

Evaluating strategies and equipment play a critical role in materials examination laboratories for assessing the mechanical, physical, and chemical residential properties of various materials. These methods and tools are essential in making sure the top quality, reliability, and safety of products made use of in different industries such as aerospace, automotive, building, and clinical.One frequently made use of testing strategy in materials test laboratories is mechanical screening, which involves subjecting materials to various forces or tons to identify their toughness, solidity, ductility, and various other mechanical residential or commercial properties. This is commonly done making use of tools such as global screening equipments, which can use tensile, compressive, and flexing pressures to examine samplings.

Physical screening strategies are additionally used to analyze properties such as thickness, thickness, thermal conductivity, and electric conductivity. Tools such as thickness meters, viscometers, thermal conductivity analyzers, and electrical conductivity meters are made use of to execute these examinations properly.

Chemical screening methods are utilized to identify the chemical composition and purity of products. Strategies such as spectroscopy, chromatography, and mass spectrometry are commonly made use of, together with specific equipment made for these objectives.

Applications of Products Examination Outcomes

The outcomes of products checking supply important understandings right into the efficiency and viability of various products for details applications in numerous sectors - materials test lab. These examination results play a crucial role in determining the quality, resilience, and safety of materials used in making proceduresAmong the key applications of materials test results remains in the area of building. Architects and designers count on these outcomes to pick proper materials for building structures, such as bridges, high-rises, and property buildings. By conducting examinations on products like hardwood, concrete, and steel, they can make certain that these materials meet the called for requirements and can hold up against different environmental problems.

In the aerospace market, materials examination results are crucial in figuring out the suitability of materials for airplane elements. By subjecting products to strenuous testing, designers can evaluate their mechanical residential or commercial properties, resistance to warmth and corrosion, and capacity to endure high-stress problems. This information is critical in making sure the safety and dependability of aircraft.

Future Fads in Materials Screening

In the world of products testing, developments in products testing methodologies are forming the trajectory of the area, ushering in a new era of technology and accuracy. One future pattern in materials screening is the combination of artificial knowledge (AI) and equipment discovering algorithms right into screening processes. These approaches great post to read enable for the assessment of product buildings without causing damages or modification to the example, making them suitable for evaluating valuable or irreplaceable materials.Verdict

Finally, materials screening plays a critical function in various sectors by making sure the quality, security, and performance of materials made use of in products and frameworks. It entails evaluating a vast array of products using numerous techniques and devices to evaluate their mechanical, physical, and chemical residential properties. The results gotten from materials screening are made use of to make informed choices in product layout, selection, and manufacturing processes. As innovation developments, products testing labs will certainly remain to adjust and improve their methods to satisfy the progressing demands of industries.Through a combination of innovative strategies and customized tools, products test labs are able to assess the residential or commercial properties of metals, polymers, composites, and various other products under different conditions and stressors. By conducting examinations on products like steel, concrete, and lumber, they can make certain that these materials meet the called for criteria and can stand up to various environmental problems.

In the aerospace market, products examination results are essential in establishing the viability of materials for airplane elements. By testing products for their resistance, stamina, and our website adaptability to influence, suppliers can choose the most appropriate materials for various automotive parts, such as body panels, engine parts, and safety and security features.In the world their website of materials screening, advancements in products examining approaches are forming the trajectory of the area, ushering in a new age of development and accuracy.

Report this wiki page